About Us

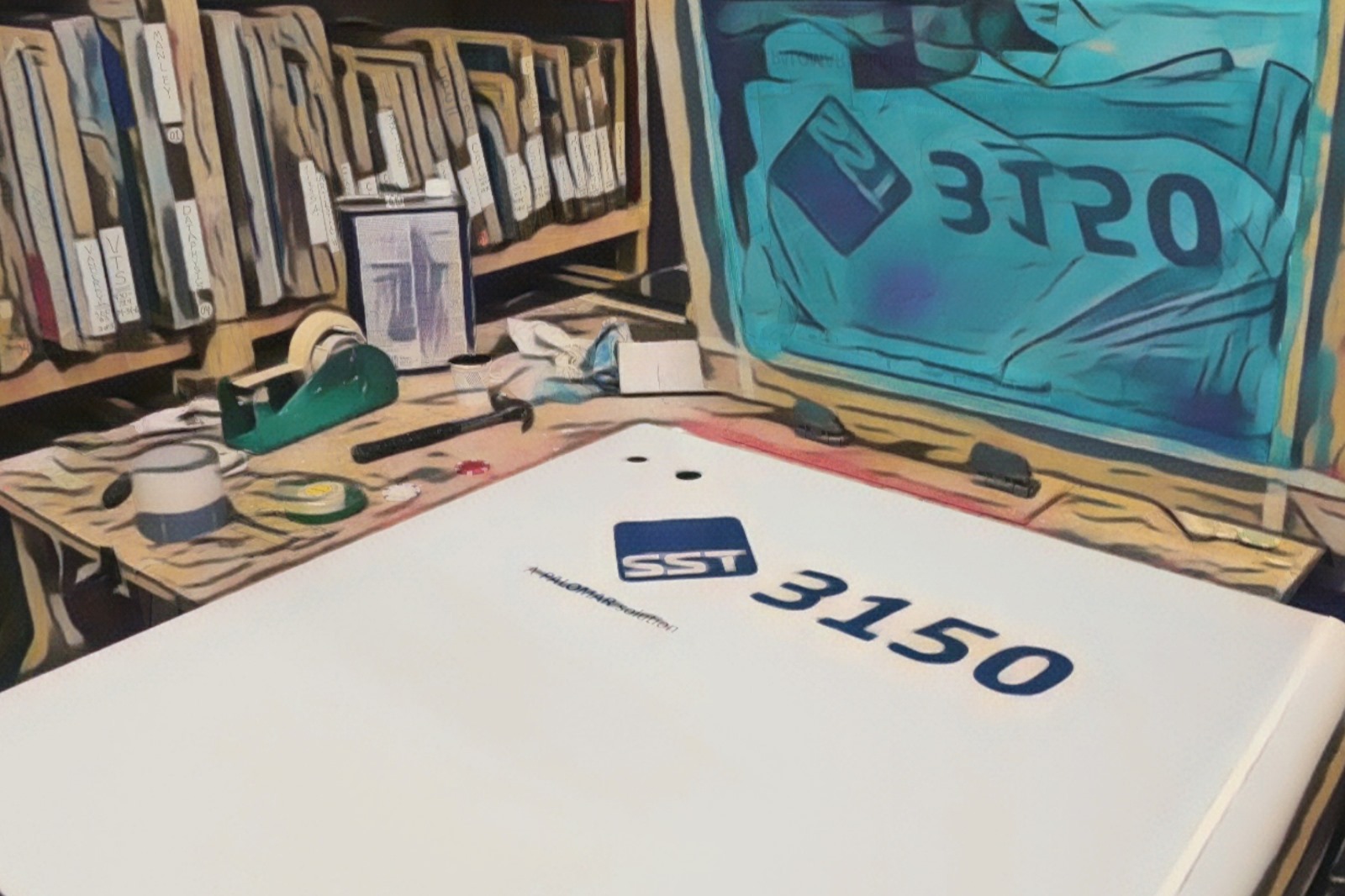

INDUSTRIAL METAL PRINTING

Our service is direct printing on all types of fabricated product using the silk screen process. Our team has decades of experience on this specific field. We are dedicated to perfection and committed on delivering outstanding results. We are also very well aware that in this business, a quick turn around is crucial the majority of the time.

We specialize in silk screen printing on fabricated sheet metal and machined parts, for a variety of applications including marking, branding, and decorative purposes. This silk screening may concern the electronics, a or the medical industry. We print on a variety of products , including front panels, chassis, enclosures and these

products could be unfinished, electroplated, painted or Powder Coated. Our service may applies to the manufacturing industry including powder coat, sheet metal fabrication companies.

OUR PROCESS

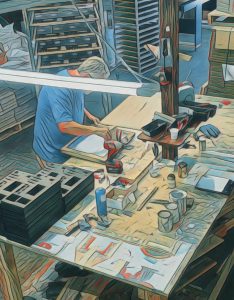

INDUSTRIAL METAL PRINTING takes pride in each step that it takes to achieve a quality end result. By explaining

our procedures to our customers, they are comfortable knowing and thus explaining it to their ultimate end users if the issue presents itself.

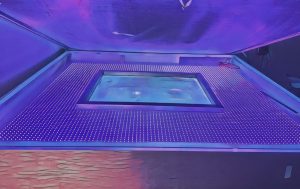

Another important step in the silk screen processes is the tooling process and manufacturing of our in-house screens. With our selection of quality emulsion and high mesh fabric, we are able to make consistent quality screens ready for production.

The main process is the actual printing onto the customer’s product. Our printers are experienced in making the necessary set ups required to print the many different shapes and sizes of product we receive. Some of the talents our printers demonstrate are; printing on curved surfaces, recessed surfaces, textured surfaces, flanges & inside boxes. Our printing can be from prototypes to long production runs. We use quality inks that best fit the particular products we are printing. We can custom mix colors using: epoxy, vinyl and enamel inks.

OUR SPECIFICS

INDUSTRIAL METAL PRINTING uses premium epoxy, enamel and vinyl inks to ensure excellent adhesion on powder-coated, liquid-painted, anodized, and raw surfaces. We use a two-component, epoxy-base inks that meet 1SO 12647-2. The ink is resistant to acids, alkalies, solvents, salt spray, thermal shock, and is qualified to meet Military spec to MIL-1-43553 and Aa56032.